There is a saying that a picture is worth a thousand words. Might I so boldly add that a picture is also worth a thousand opinions that are based, for all intents and purposes, entirely on ignorance?

There is a saying that a picture is worth a thousand words. Might I so boldly add that a picture is also worth a thousand opinions that are based, for all intents and purposes, entirely on ignorance?During my research for this article I encountered various opinions about the Automated Safety Hitch System across the broad spectrum of RV forums. One wonders how a product can be sold when so many uneducated opinions are shared about a product that they know nothing about. Why do people do this? Is it fear? Is it the unknown? Is it the desire to feel smart? Or, do they believe that their learned and comfortable way is the only way? Well, I’m not a psychiatrist and I will not venture to answer these questions.

While I was in Odessa, TX, a client E-mailed me and asked for my opinion on the Automated Safety Hitch System. I’d never heard of it and after reviewing the hitch system website, I decided to take a detour from my planned route and head to Denton, TX, where the manufacturing plant is located. Denton is located about 30 miles north of the Dallas/Fort Worth metro area. During the course of two meetings, I met and received a warm welcome from Joe Jamieson who is the CEO of Automated Safety Hitch, Inc. and the inventor of the Automated Safety Hitch System.

|

| No spot welding on this product. |

As Jamieson, who has an aeronautics degree and an extensive working background in this field, guided me through the plant, he explained the details of the manufacturing process. Fortunately for me, I am gifted with understanding mechanical things. Jamieson builds the hitch frames and bodies from US grade steel, some of which is one quarter inch thick. You will not find spot welding on his products. All the welds are full length and exterior body welds are ground down to a smooth finish. This is very uncommon in today’s industry. The thought came to me that if someone began shooting at me with a high powered rifle, I’d want to take cover behind the Automated Safety Hitch System! When it comes to construction, Jamieson does not take shortcuts. When asked why he goes the extra mile, his reply is, “So I can sleep well at night.”

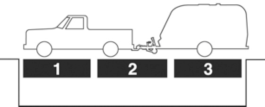

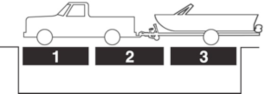

One commented on an RV forum, “I do not like the looks of that thing”. It does have an unusual appearance at first glance. But, after studying it and understanding how it operates, it grows on you. It doesn’t take long to realize the Automated Safety Hitch System is one of the most innovative RV safety products on the market. Jamieson states that braking is improved by as much as 50% and, as I test drove it, I believe it. During my test drive I towed a two axle horse trailer and I could easily stop just by activating the brake controller only. Very little pressure is required to brake with the truck’s brake pedal. Turning around corners and maneuvering through traffic is a breeze with the steerable axle that locks straight automatically when not doing slow tight turns. It’s fascinating to watch the trailer as it swings about 14 inches to the outside away from the turn while maneuvering a tight corner. The horse trailer tires cleared the island by 3 feet as I was navigating through a tight left turn. Towing with the hitch system allows drivers to travel centered in the lane as opposed to pulling to one side of the lane to make the turn. The hitch owners I questioned did not feel uncomfortable during tight turns nor had any motorist honked their horn at them. Additionally, backing the trailer is akin to backing a bumper pull trailer, as I quickly learned.

The other amazing feature about the hitch system is the ability to increase the towing capacity of tow vehicles by 50 percent. This is primarily due to the increased braking capacity. I do think one would have to use some common sense and consider the capability of the tow vehicle’s powertrain, especially when considering the number of times an RVer may be towing up steep inclines. Typically, when towing any fifth wheel or heavy gooseneck trailer, a diesel engine vehicle with a towing package is first choice for towing. On the other hand, the Toyota Tundra towed the Space Shuttle! RV consultant Bob Zagami said it well, "It is not how much you can tow, it is how much you can control and stop that is important!"

|

| Steerable axle with Bendix hydraulic brakes. |

The maximum hitch weight is rated for 6,300 pounds but can be upgraded to 8,000 pounds. The steerable axle is a Dana 70 series and is equivalent to those used on one ton and one and one-half ton trucks. The axle is equipped with Bendix heavy duty hydraulic disk brakes and has vented rotors and is powered by the onboard hydraulic system. The unit also includes a battery and electrical system to power the onboard equipment. Jamieson told me about one of his customers who shared the scary moment when his truck engine suddenly shut down while towing down the highway, therefore, almost losing the truck brakes and the steering becoming difficult. Fortunately, the owner had a cool head and reached down to the trailer’s break controller and performed a well-controlled and safe stop.

For RVers who are contemplating upgrading from a three-quarter ton vehicle to a one ton truck, they may not have to. I, for one, wish I had known about this hitch system before I traded in my new Ram 2500 for a new 3500 dually in early 2009. The Automated Safety Hitch System certainly has the potential to save some money considering one may not have to upgrade. For example, in my own personal case, not only did I trade in my 2500, I ended up throwing in my fairly new Toyota Tacoma valued at $15,700. Depending on options and customizations, the Automated Safety Hitch System could range in price from $10,000 to $11,000, including everything needed (such as a customized class five hitch rated for 30,000 pounds) for your vehicle to pull your trailer. That may seem like a hefty price tag, but when considering that upgrading to a one ton vehicle for about $30,000 or more and the unprecedented safety features this hitch system provides, as well as other cost saving features mentioned on Jamieson’s website, the price tag is less of an issue. As for long term customer service, hitch owners will receive hitch improvement upgrades at no charge, excluding the cost of delivery.

Included with each unit sold is a notarized letter indicating the regulatory compliance in 9 continents and regions stating that the Automated Safety Hitch System is classified as a lift/drop axle, not as a trailer. Therefore, registration with state and county motor vehicle departments is not required. The letter also states that the additional seven to nine feet should not be added because “the length of devices determined to be necessary for safe and efficient operation should be excluded.” Several states have laws that exempt the lift/drop axle from the length limitation. Jamieson said that none of his customers have reported being ticketed for length violations and that was confirmed by the customers I interviewed for this report. Customers surveyed also revealed that the Safety Hitch has been used in nearly every state and in Canada without any problem. There are additional links below covering state RV length laws. If unsure, contact your local state agency.

The future of the Automated Safety Hitch System

As I was about to depart our second meeting, I commented to Jamieson that the Automated Safety Hitch System could revolutionize the RV industry if the hitch system was integrated into all fifth wheel and gooseneck trailers. That led to another 15 minutes of conversation. Just think about it, not only would trailers become tremendously safer to control and stop, the nose area of these RVs could gain up to one foot of headroom. The trailer’s ground clearance could be reduced, improving controllability and safety. The overall height could be reduced and result in aerodynamic advantages such as less induced drag, less upper laminar parasite drag and less lower turbulent parasite drag. There would be no more concern about keeping good height above the truck bedrails. Trailers could be towed level instead of nose high creating less drag and improving fuel mileage and weight distribution on the trailer axles. The distance of the kingpin location could be moved back closer to the trailer axles resulting in improved control. The trailer’s GVWR could also be increased while tow vehicles would not necessitate such a change, which is especially important for toy hauler and full-timer owners. I do think it’s time for the RV industry to seriously consider integrating this hitch system into fifth wheel and gooseneck trailers!

There are far more benefits to using or integrating the Automated Safety Hitch System than the one disadvantage noted on RV forums, which is reduced weight over the truck’s rear axle. Jamieson noted that that is why he recommends owners use a tow vehicle with four wheel drive for those situations that require additional traction. Although rare, some of the interviewed customers have indicated they had to switch to four wheel drive for some situations. On the other hand, the truck bed has been freed up to carry cargo that was once limited. One other significant advantage of this hitch system is that it opens the field of tow vehicle choices that have been pretty much limited to long wheelbase diesel trucks when towing big and heavy trailers.

Hmm… You may just see an ATV and a couple of Segways coming out of my covered truck bed someday. A new larger replacement fuel tank would be in order, too. What would you fill your truck bed space with once you’ve eliminated the fifth wheel hitch?

To learn more and watch numerous videos of the Automated Safety Hitch System in action, visit Jamieson’s website at http://automatedsafetyhitch.com or call him at 1 (866) 465-1454.

RV Road Use Laws – RVDA

Trailer Dimensions – AAA

State Towing Laws for RVs - NSA RV Products

Towing World RV Laws

RV Road Use Laws – RVDA

Trailer Dimensions – AAA

State Towing Laws for RVs - NSA RV Products

Towing World RV Laws

RV Rigs Using the Automated Safety Hitch System

|

| This RVer wanted to haul his Jeep and tow his fifth wheel trailer. |

|

| This 2012 Chevrolet Suburban is prefect for this family of four and their 197 pound English Mastiff. |

|

Do you have a lifted truck?

It's not a problem when towing with the Automated Safety Hitch System.

|

|

| This 2012 Ford F-250 4X4 has no problem controlling this heavy 40 foot triple axle RV. |

Copyright © 06/30/2013, Dave Gray, Reprint by permission only.